NIPPON KINZOKU Launches Full-Scale Expansion of “Eco-Product” Using Innovative Composite Metal Forming Technology Based on “Fine Profile”

Released on: Tuesday, 13 Jan 2026 11:39AM

Achieving production efficiency and enhanced supply chain environmental performance through process shortening and material loss reduction

TOKYO, Jan 13 (Bernama-BUSINESS WIRE) -- NIPPON KINZOKU CO., LTD. (TOKYO: 5491) (Headquarters: Minato-ku, Tokyo) has commenced the full-scale deployment of its "Eco-Product" lineup, comprised of products manufactured using its proprietary "Composite Metal Forming Technology," which is based on the long-cultivated precision profile-rolled products, "Fine Profile."

This press release features multimedia. View the full release here: https://www.businesswire.com/news/home/20260112730478/en/

By utilizing this technology that enables processing close to the final product shape, we will contribute to our customers' process shortening and material yield improvement, aiming to reduce environmental impact across the entire supply chain and realize a carbon-neutral society.

Background and Purpose of Development

In recent years, the manufacturing industry faces the urgent challenge of reducing both costs and environmental impact. Particularly in metal component processing, material waste and energy consumption during manufacturing processes have been major issues. Against this backdrop, our company has been developing and enhancing our unique “Composite Metal Forming Technology” by combining the diverse metal processing technologies.

Features of Composite Metal Forming Technology

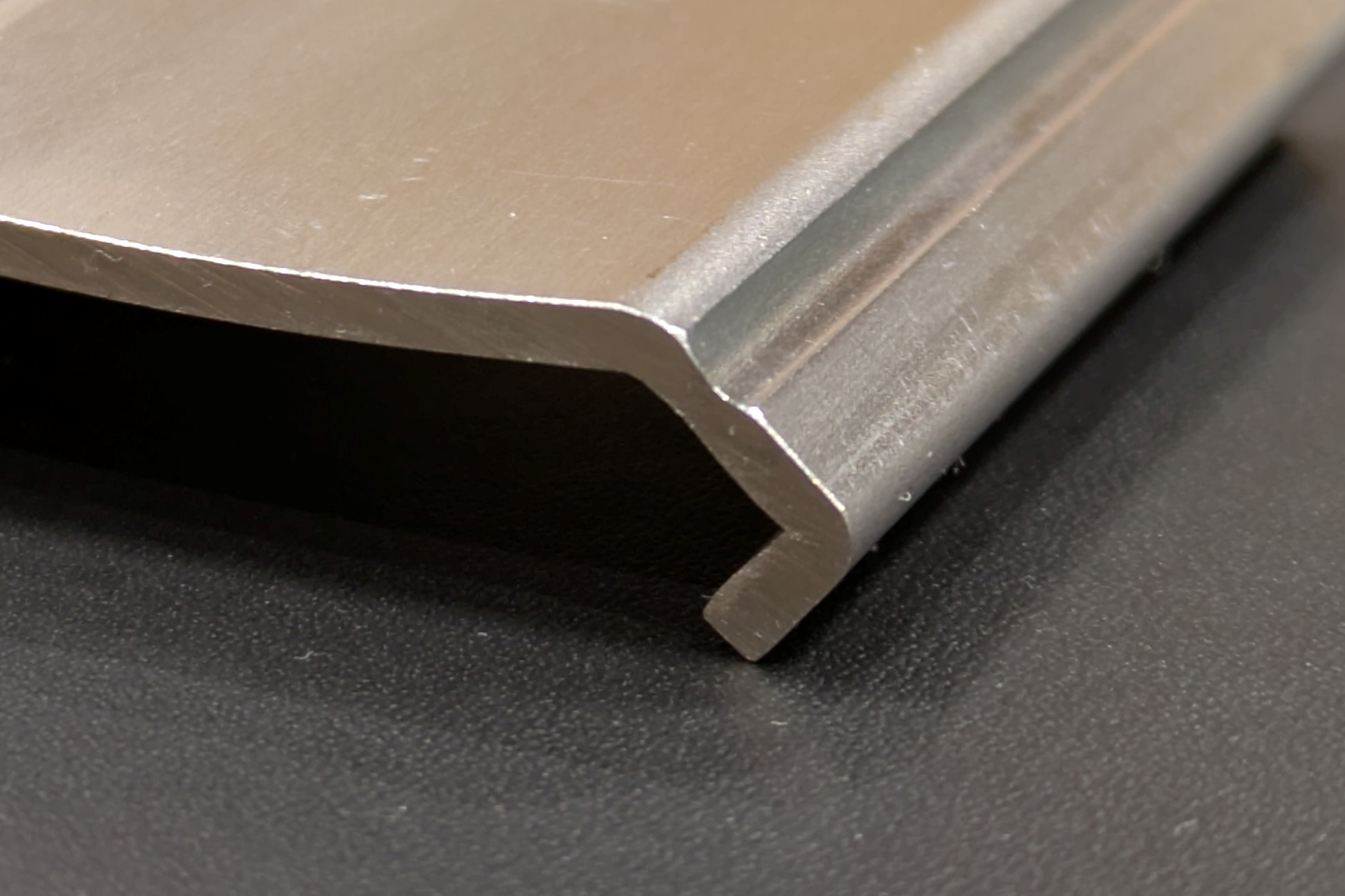

Achieving complex cross-sectional shapes and significantly reducing material loss

Based on our “Fine Profile”, we efficiently shape them into near-final shapes within our own factory by combining processing technologies such as roll forming and pressing. This minimizes customer machining, improves material yield, and contributes to waste reduction.

Elimination of customer manufacturing processes and increased productivity.

By handling all subsequent processes, such as press forming and sheet metal fabrication, that customers previously arranged, we can deliver components. This significantly shortens your manufacturing process, improving productivity while reducing the energy consumption and CO₂ emissions associated with transportation and storage across multiple stages.

Stable high quality through continuous coil material forming

The continuous formation of coil-shaped materials enables the production of long materials with minimal shape variation and stable quality, as well as highly efficient drilling processes. This helps ensure stable production for our customers and reduces the occurrence of defective products.

Based on these features, products utilizing this technology contribute to optimizing material usage, reducing energy consumption, and minimizing waste volume.

Click here for more details.

https://www.nipponkinzoku.co.jp/assets/images/2026/01/20260113-En-Press-Release.pdf

About NIPPON KINZOKU Group

Our products have been used in a range of areas from the precision field to the construction industry. https://www.nipponkinzoku.co.jp/en/

View source version on businesswire.com: https://www.businesswire.com/news/home/20260112730478/en/

Contact

NIPPON KINZOKU CO., LTD.

Production Process & Support Department

https://www.nipponkinzoku.co.jp/en/inquiry

Source : NIPPON KINZOKU CO., LTD.

--BERNAMA

Background and Purpose of Development

In recent years, the manufacturing industry faces the urgent challenge of reducing both costs and environmental impact. Particularly in metal component processing, material waste and energy consumption during manufacturing processes have been major issues. Against this backdrop, our company has been developing and enhancing our unique “Composite Metal Forming Technology” by combining the diverse metal processing technologies.

Features of Composite Metal Forming Technology

Achieving complex cross-sectional shapes and significantly reducing material loss

Based on our “Fine Profile”, we efficiently shape them into near-final shapes within our own factory by combining processing technologies such as roll forming and pressing. This minimizes customer machining, improves material yield, and contributes to waste reduction.

Elimination of customer manufacturing processes and increased productivity.

By handling all subsequent processes, such as press forming and sheet metal fabrication, that customers previously arranged, we can deliver components. This significantly shortens your manufacturing process, improving productivity while reducing the energy consumption and CO₂ emissions associated with transportation and storage across multiple stages.

Stable high quality through continuous coil material forming

The continuous formation of coil-shaped materials enables the production of long materials with minimal shape variation and stable quality, as well as highly efficient drilling processes. This helps ensure stable production for our customers and reduces the occurrence of defective products.

Based on these features, products utilizing this technology contribute to optimizing material usage, reducing energy consumption, and minimizing waste volume.

Click here for more details.

https://www.nipponkinzoku.co.jp/assets/images/2026/01/20260113-En-Press-Release.pdf

About NIPPON KINZOKU Group

Our products have been used in a range of areas from the precision field to the construction industry. https://www.nipponkinzoku.co.jp/en/

View source version on businesswire.com: https://www.businesswire.com/news/home/20260112730478/en/

Contact

NIPPON KINZOKU CO., LTD.

Production Process & Support Department

https://www.nipponkinzoku.co.jp/en/inquiry

Source : NIPPON KINZOKU CO., LTD.

--BERNAMA